Asbestos gasket is not a term commonly come across in the modern building trade.

It evokes a blend of historical significance and modern concern.

But what exactly is an asbestos gasket?

Delving into this topic unveils not only the mechanical intricacies of this industrial component but also the complex history and potential hazards it carries.

This article takes you on a journey through the layers of understanding, exploring the origins, applications, and the crucial awareness surrounding asbestos gaskets in today’s safety-conscious world.

Table of Contents

What is an Asbestos Gasket?

An asbestos gasket is a mechanical seal designed to fit between two surfaces to prevent leakage under compression.

What makes these gaskets unique is their composition; they contain asbestos fibres, a naturally occurring mineral known for its heat resistance and durability.

Asbestos gaskets were widely used in various industrial applications, especially during the 20th century, due to their remarkable ability to withstand high temperatures and pressures.

These gaskets came in different types, each tailored for specific applications.

Despite their practical applications, asbestos gaskets posed significant health risks.

Due to these health hazards, the use of asbestos gaskets and other asbestos-containing materials has been banned in many countries, including the United Kingdom, to protect public health and safety

Why was an Asbestos Gasket Used?

An asbestos gasket was extensively used primarily due to its exceptional heat resistance and ability to withstand high pressures.

Composed of asbestos fibres, a mineral known for its insulating properties, these gaskets proved ideal for applications involving extreme temperatures or pressure differentials.

Asbestos fibres provided excellent insulation against heat, making them valuable in industries where machinery operated at high temperatures.

Moreover, these gaskets were versatile and cost-effective, making them a popular choice across various sectors, including manufacturing, automotive, and power plants.

The unique properties of asbestos made it an attractive material for creating durable and reliable gaskets, despite the risks that later became apparent.

Where would you find an Asbestos Gasket?

Asbestos gaskets found their way into a wide array of different industries.

Automotive Engines and Exhaust Systems

Asbestos gaskets were a common sight in the intricate mechanisms of automotive engines and exhaust systems.

Their heat resistance made them ideal for sealing joints and connections, especially in high-temperature areas like exhaust manifolds.

These gaskets ensured that no exhaust gases leaked out, maintaining the efficiency and safety of the vehicle’s operation.

Industrial Machinery and Equipment

In industrial machinery, asbestos gaskets found their niche.

From manufacturing plants to processing units, these gaskets were employed in various equipment.

Their ability to withstand heat and pressure made them essential for sealing joints in heavy machinery, ensuring the seamless operation of manufacturing processes and preventing leaks that could disrupt production.

Heating Systems and Boilers

Heating systems and boilers, where extreme temperatures and pressure differentials are commonplace, relied heavily on asbestos gaskets.

They were instrumental in sealing joints and connections within these systems, guaranteeing that no heat escaped and that the systems function efficiently.

Asbestos gaskets were crucial components for maintaining the integrity of heating systems, whether in residential homes or large industrial complexes.

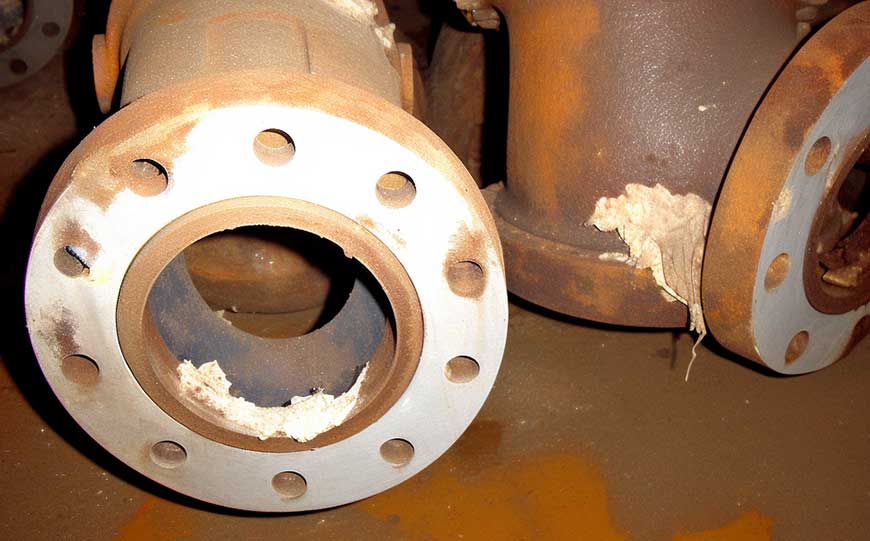

Piping and Plumbing

Asbestos gaskets were extensively used in piping and plumbing systems.

Their heat resistance and sealing capabilities made them valuable for ensuring leak-proof connections in pipes carrying various substances, including water, chemicals, and gases.

Whether in residential plumbing or industrial pipelines, these gaskets played a vital role in preventing leaks and maintaining the structural integrity of the systems.

Electrical Appliances and Transformers

Even in electrical appliances, asbestos gaskets were present.

They were utilised in appliances like transformers, where heat generated during operation needed to be effectively managed.

Asbestos gaskets provided reliable seals, preventing heat from escaping and ensuring the safe and efficient functioning of electrical equipment.

Despite the risks associated with asbestos, these gaskets were prevalent in various electrical devices before safer alternatives became the norm.

What Types of Asbestos Gaskets were used?

Each type of asbestos gasket was designed to serve a specific purpose, a testament to the diverse demands of various applications.

Spiral Wound Gaskets

One of the common types of asbestos gaskets was the spiral wound variety.

These gaskets consisted of a V-shaped metal strip embracing a soft filler material, often interlaced with asbestos fibres.

This intricate design bestowed these gaskets with unique resilience, allowing them to adapt effortlessly to fluctuating pressure conditions.

Spiral wound gaskets acted like chameleons in the gasket world, ensuring a tight seal even in the face of varying pressures.

Their adaptability made them a preferred choice in industrial settings where pressures inside mechanical systems could fluctuate significantly.

Asbestos Sheet Gaskets

Asbestos sheet gaskets were another prevalent type, known for their solidity and versatility.

Crafted from compressed asbestos fibres expertly blended with fillers and binders, these sheets were remarkably adaptable.

Their flexibility allowed them to be cut into specific shapes, transforming them into sealing solutions tailored for various needs.

Whether it was the curves of a valve or the straight edges of a pipe, asbestos sheet gaskets moulded themselves to fit, providing a customised seal where it was needed the most.

Their ability to conform to different surfaces made them indispensable in industries where a tailored seal was imperative.

Asbestos-Rubber Gaskets

In an asbestos-rubber gasket, asbestos fibres were combined with the elasticity of rubber, creating a gasket that stood firm under pressure while flexing when necessary.

This amalgamation of materials made them particularly effective in applications where both endurance and adaptability were paramount.

The rubber provided the necessary flexibility, allowing the gasket to maintain a seal under varying conditions, while the asbestos fibres reinforced its strength, ensuring durability and longevity.

What are the Dangers of an Asbestos Gasket?

Asbestos has many dangers associated with it.

Inhalation Risks

Within the seemingly innocuous seal of asbestos gaskets lurked a microscopic peril: asbestos fibres.

When these gaskets were disturbed, especially during maintenance or repairs, these tiny fibres could become airborne.

Inhalation of these particles presented severe health risks.

Asbestos fibres, once lodged in the lungs, could cause devastating diseases, including asbestosis, lung cancer, and mesothelioma.

The insidious nature of these illnesses lay in their latency period; symptoms often emerged years, sometimes decades, after exposure.

This made pinpointing the exact cause of these diseases challenging, emphasising the critical importance of identifying and safely removing asbestos-containing materials for the public’s well-being.

Environmental Contamination

The dangers of asbestos gaskets extended beyond human health, posing significant threats to the environment.

Improper disposal or degradation of these gaskets could lead to the release of asbestos fibres into the soil and water, contaminating ecosystems.

Once infiltrating the environment, these fibres became hazardous for wildlife, potentially disrupting local ecosystems.

Due to asbestos’s durable nature, these fibres persisted in the environment for an extended period, ensuring their impact was both long-lasting and pervasive.

Proper disposal methods and stringent regulations became paramount, serving as vital safeguards against the environmental dangers associated with asbestos gaskets.

When was it made Illegal to use an Asbestos Gasket?

In the United Kingdom, the use of asbestos-containing materials, including asbestos gaskets, was banned in 1999.

These regulation changes marked a significant turning point in public safety regulations.

The ban came as a response to growing awareness about the severe health risks associated with asbestos exposure, including diseases like asbestosis, lung cancer, and mesothelioma.

Prohibiting the use of asbestos gaskets was a crucial step towards safeguarding the health and well-being of workers, consumers, and the general public.

The ban not only halted the production and use of asbestos-containing products but also prompted a focused effort on asbestos removal and safe handling practices, ensuring a healthier environment for everyone.

Conclusion

Asbestos gaskets were once hailed for their resilience, and are now a cautionary chapter in industrial history.

Understanding their past significance and the associated dangers is essential in the ongoing efforts to mitigate asbestos-related risks.

As industries continue to evolve, the lessons learned from asbestos gaskets remind us of the importance of prioritising safety and awareness in material choices, ensuring a healthier and safer future for all.